Water Ring Vacuum Pump Working Principle Ppt

Find out how the nash liquid ring vacuum pump w.

Water ring vacuum pump working principle ppt. With the benefits of liquid ring technology whilst saving water and saving energy you get a liquid ring module that works for you. Liquid ring pump can also be used as compressor it belongs to low pressure compressor. As the shaft turns a liquid ring is created by the centrifugal force generated by the rotating impeller. Easy maintenance longer pump life liquid ring vacuum pumps are robust in construction and have only one moving part the rotor which is mounted on a shaft supported by a set of bearings designed for a long service life of continuous operation.

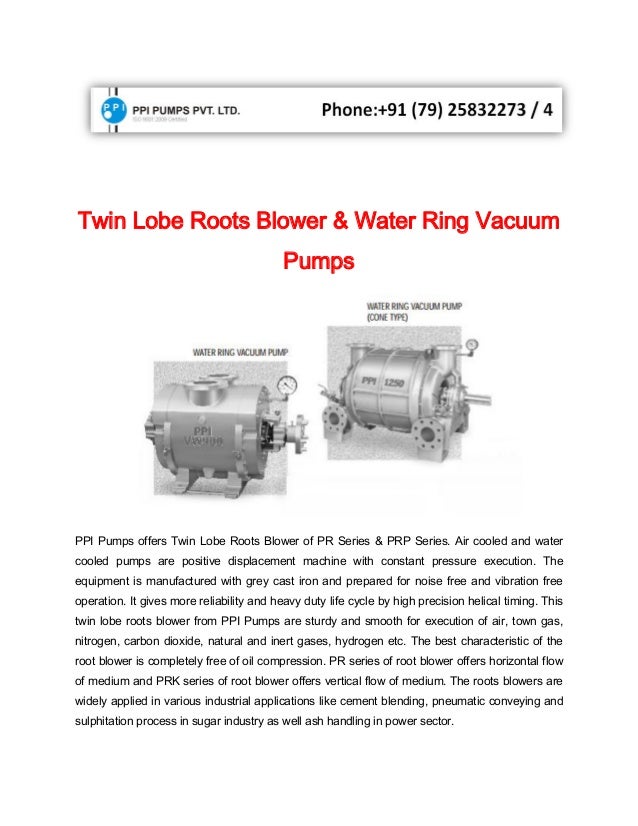

The inlet valve is designed as a. This benefits the user with less wear and simpler affordable maintenance. The outlet valve is oil sealed. Liquid ring vacuum pump also called liquid ring vacuum pump for short is a kind of coarse vacuum pump which can obtain pressure.

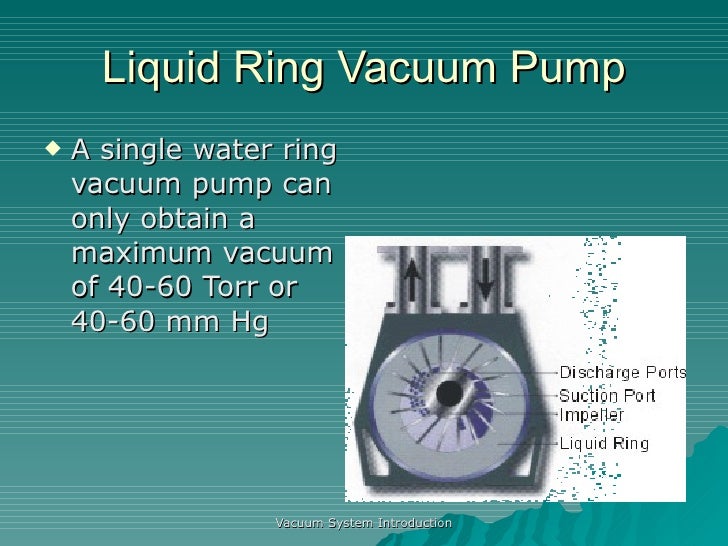

To produce vacuum in a two stage liquid ring vacuum pump a multi blade impeller on a shaft is positioned eccentrically in a cylindrical housing that is partially filled with sealing liquid. We take the hassle out of selecting your vacuum system. They operate according to the positive displacement principle. Basically between the inlet and discharge ports you have a rotary equipped inner.

As shown in the diagram of the working principle of the liquid ring pump the liquid ring pump is. The components of a liquid ring vacuum pump. In these machines a liquid is made to act as a piston. A liquid ring pump is a rotating positive displacement pump.

They are typically used as a vacuum pump but can also be used as a gas compressor the function of a liquid ring pump is similar to a rotary vane pump with the difference being that the vanes are an integral part of the rotor and churn a rotating ring of liquid to form the compression chamber seal. Its pressure range is 1 2 x105pa gauge pressure under specific conditions. Liquid ring vacuum pumps have six basic parts and can also be augmented with numerous accessories. For more than 110 years nash liquid ring technology has provided reliable solutions for process applications.

The parts that comprise a liquid ring vacuum pump and perform its key functions are relatively simple. The pumping system consists of a housing 1 an eccentrically installed rotor 2 vanes that move radially under spring force 3 and the inlet andoutlet 4. Environmental pumps do not require an oil change filter oil pans. Through the centrifugal installation of impeller and pump chamber the purpose of suction compression and exhaust is achieved and the vacuum i e.