Warm Forming Aluminum Sheet

Because of the complexity of various parts and lack of knowledge base further development work is needed to establish design guidelines for warm forming.

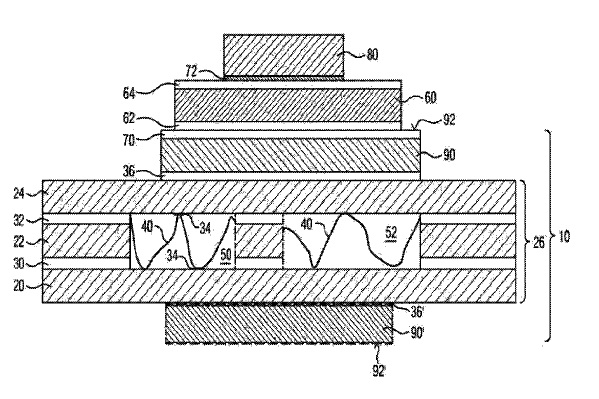

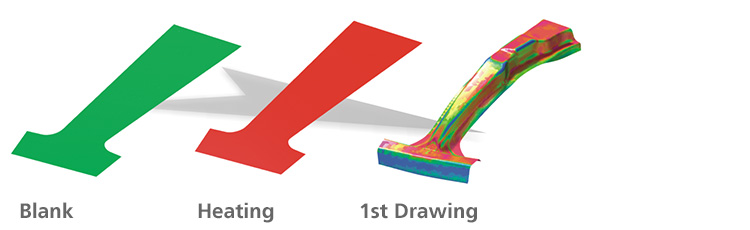

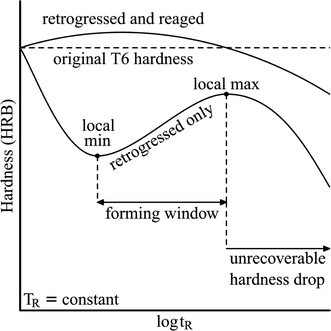

Warm forming aluminum sheet. In fact elevating the temperature or warm forming of aluminum sheet at reasonable production rates and acceptable costs has become a realistic alternative to straight stamping. Established forming process limits for both commercial al and mg sheet. Aluminum sheet alloys only typically posses moderate formability at room temperature limiting their design applications. The first approach is a warm forming route to form sheets in t6 temper state with high tensile strength at temperatures between 150 c and 300 c.

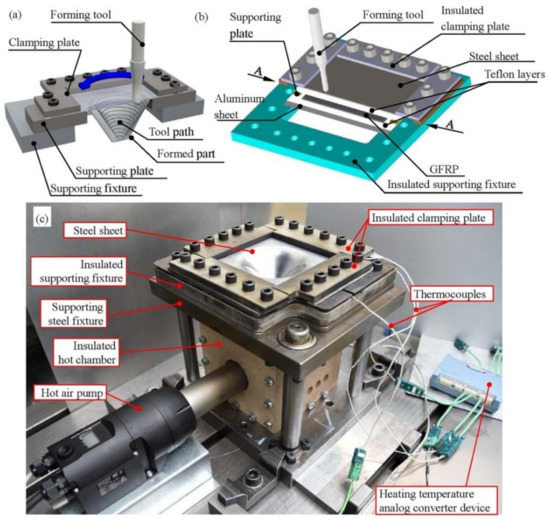

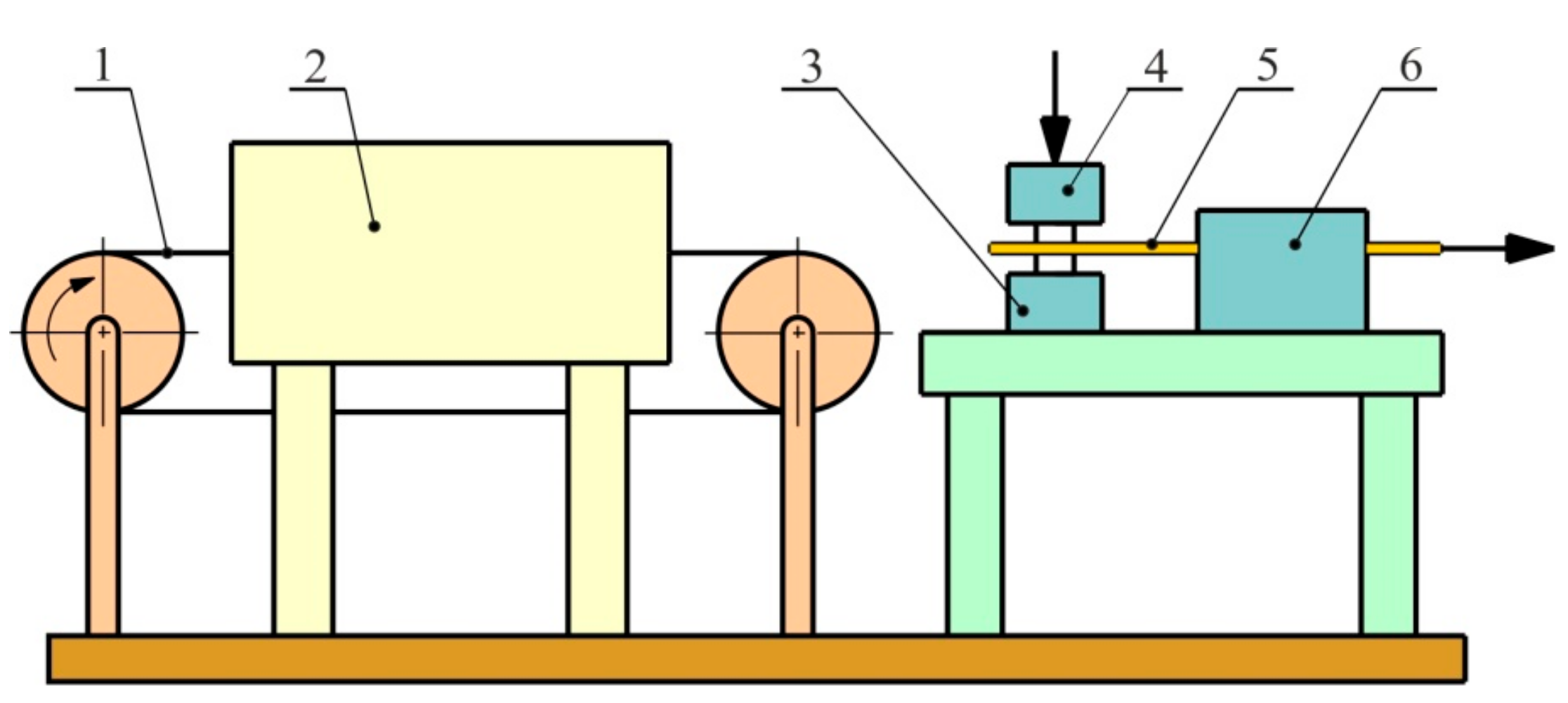

Warm forming technology is a promising approach to improve the formability of peak aged 7075 aluminum alloys aa7075 t6 5 6 7 8 where the aa7075 t6 blank is heated to target temperatures. Aluminum at elevated temperatures. Formability was studied by forming rectangular parts at a rapid rate of 1 s 1 using internally heated punch and die for both isothermal and non. Developed fully automated warm forming cell capable of demonstrating the process under run at rate conditions at 5 jobs per minute for both aluminum and magnesium.

Three sheet alloys were used for the present biaxial warm forming tests namely the strain hardenable aluminum alloys al 5754 and al 5182 mn and the precipitation hardenable alloy al 6111 t4. This video shows a warm forming trial at ewi forming center with aa 6xxx 7xxx. Warm forming of aluminum sheet has emerged as a way to increase ductility and formability. Introduction sheet metal aluminum alloys are prime candidates for use in the automotive industry because of their good strength and stiffness to weight ratios.

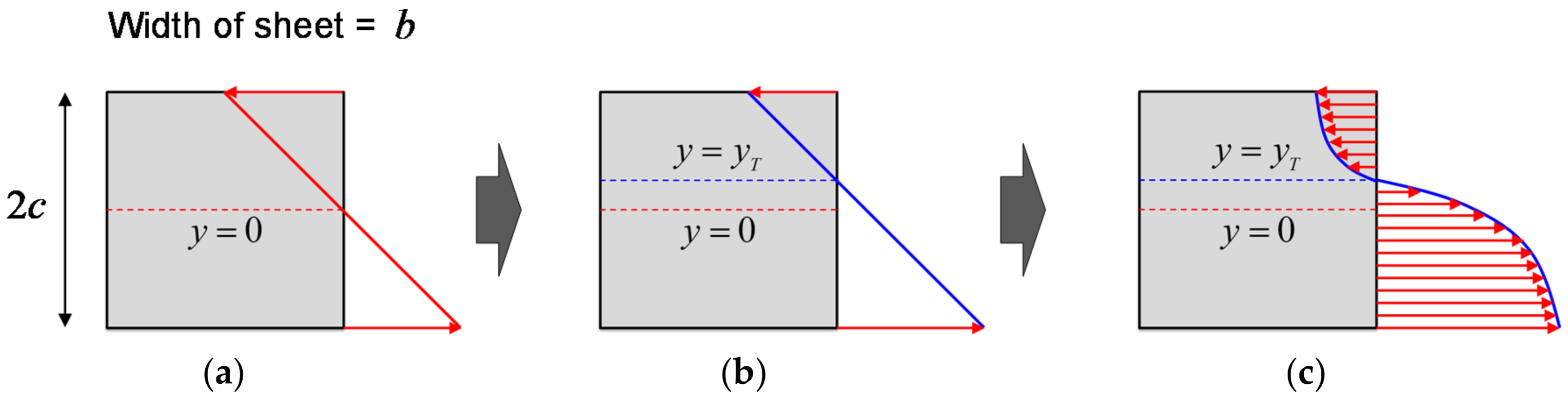

However since it can be carried out using a standard cold. The alloy al 5182 mn was modified from commercial alloy 5182 by adding about 1 mn as dispersoid former for the enhancement of the strain rate. Warm forming of aluminum alloys offers the possibility of drawing complex aluminum sheet products which cannot be manufactured at room temperature without extra forming and joining operations. Developed finite element prediction of forming and failure during warm forming.

Ing warm forming does not impart high ductility stretch formabili ty to the material. However for a general purpose aluminum alloy warm forming offers better deep drawability than cold forming 3 9 warm forming has not yet been applied in automotive parts pro duction. Warm forming of these alloys can significantly improve their formability and this is the main.